Diesel Progress Magazine Covers Mirenco

Electronic Technology Designed to

Eliminate the "Lead Foot"

by Bill Siuru |

|

As any fleet manager knows, different drivers can turn in significantly

different fuel economy results when operating the same vehicle. And over time,

no matter how well maintained, the fuel economy performance of a typical truck

or bus will go down as a vehicle ages.

In an effort to address both of these issues, Mirenco, Radcliffe, Iowa, has

developed a throttle management system called DriverMax that uses patented

technology to control the throttle in real-time and reduce or eliminate the fuel

waste caused by both imprecise driver throttle control and natural engine

degradation.

"One of the simplest and most over-looked solutions to a cleaner environment and

better fuel mileage is to simple take it easy on the vehicle throttle," said

Dwayne Fosseen, Mirenco’s founder, chairman and CEO. "DriverMax can be thought

of as a device attached to the driver’s foot, not and engine modification

device. It doesn’t do anything the driver’s foot can’t do, if the driver’s foot

were very smart and could consider the current level of deterioration of the

engine’s combustion process."

Originally conceived by Fosseen during the mid-1970s fuel crises, the technique

was subsequently engineered for commercial use under a joint development

agreement with the US Dept of Energy (DOE) Kansas City Plant (KCP). The DOE

developed a microprocessor-controlled fuel management system to monitor operator

input and vehicle fuel demand. Using these inputs, DriverMax controls the

optimum fuel flow rate via a throttle modulating system. Additionally, DOE

engineers designed the microprocessor to be affordable. While DriverMax is

initially being offered for heavy duty diesel engines, the patented technology

should be applicable to other vehicles including passenger cars with gasoline

engines in the future.

Mirenco is now beginning production of an electronic actuator that will enable

installation on mechanical engines. This allows the DriverMax computer to

control the operation of the fuel injection pump. It will allow the Mirenco

technology to be retrofitted to older mechanical diesel engines, including

off-road construction and mining equipment.

The DriverMax microprocessor is installed in the wiring between the throttle

position sensor and the electronic control module (ECU). Since DriverMax is

installed and operates completely outside the engine, installation can typically

be accomplished in less than an hour, the company said. Programming DriverMax

specifically for the vehicle takes only minutes using Mirenco’s DriverMax

software with a laptop PC connected to the unit. After a unit is installed,

DriverMax is designed to be easily reprogrammed to compensate for ongoing engine

wear.

In order to maximize the benefit of DriverMax, Mirenco technicians perform an

initial emission analysis on the engine using portable exhaust analyzers. Along

with emission analysis, the technicians may use an accelerometer to determine

vehicle performance on initial acceleration. DriverMax is then programmed

according the combustion state of the engine and the vehicle’s requirements for

power. Ongoing emission analysis can detect continued combustion degradation, in

which case minor DriverMax adjustments may be made.

Testing indicates that the DriverMax system can deliver fuel savings as high as

5 to 10 percent and smoke reduction of 50 percent or higher, the company said.

The Transit Authority of River City (TARC) in Louisville KY, installed DriverMax

on 100 buses and after a year of operation TARC estimated that is has eliminated

11,000 lb of emissions while saving 43,000 gal of fuel. According to J Barry

Barker, executive director of TARC, "The installation of DriverMax throttle

modulators on buses with five to eleven years of service is one of the

initiatives we are pursuing, and we are pleased with the results to date."

The units have also been installed on tour buses operated by Harvey

Transportation in the Grand Canyon National Park where they reduced particulate

emissions by an average of 74 percent from the engines’ previous PM levels. In

speed tests, the system has had a negligible impact on speed, typically less

than one second difference from zero to 40 mph, the company said.

Recently, Mirenco conducted an extensive series of tests designed to simulate an

enclosed working environment where heavy duty diesel vehicles are operated, such

as might occur in under-ground mines or warehouses, etc. Forty four

acceleration/deceleration cycles were performed over a 10 min. period and

particulate matter measures were continuously recorded at the PM 10 to 2.5

levels. The results consistently demonstrated a 74 percent reduction in PM 2.5

levels and a 76 percent reduction of PM 10, according to Mirenco.

Payback for the DriverMax system is typically six to nine months, the company

said. The system can be purchased direct from Mirenco, but a distributor network

is also being considered.

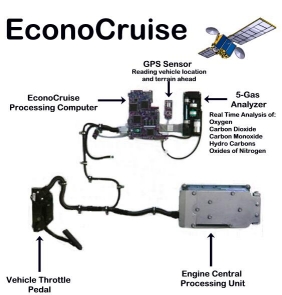

Mirenco also recently announced the next step in the application of its patents

in EconoCruise, which features satellite-to-throttle technology. As the name

implies, EconoCruise employs GPS to "learn" the topography of the roadway and

build a map of the route a vehicle travels. The system calculates and stores a

driver’s acceleration patterns along the given route, then when EconoCruise is

engaged along the same route in the future, speed and throttle control are

determined by the vehicle’s geographical location.

Follow-on versions of EconoCruise may employ a built-in database of topography

and terrain as well as real time emissions sensors, ambient conditions sensors

and relative wind calculations/adjustments, the company said.

The EconoCruise microprocessor can manage the throttle to meet the desired

performance criteria (e.g., best fuel economy, speed, and emissions tradeoff),

literally second-by-second via satellite, taking into account the topography and

terrain of the roadway, wind resistance, exhaust emissions, and engine

performance. EconeCruise, for example, allows the vehicle to gain an acceptable

and safe amount of momentum while traveling downhill or on a straightaway to

prepare for an uphill stretch of road ahead. This form of intelligent cruise

control allows less experienced drivers to achieve the same vehicle performance

as the better operators, the company said. When generating route data, the fleet

operator would use the best drivers who are familiar with both the route and the

particular truck, which could result in an optimum operational profile that

could be automatically replicated with any driver.

Like current cruise controls, the driver can override EconoCruise by tapping the

brakes or pressing the foot throttle. First successfully demonstrated in 1999,

the system is currently being refined under Mirenco’s second development

contract with the DOE. Production units are estimated to be available for heavy

duty trucks sometime in this quarter.

About Mirenco

Mirenco is a Radcliffe, Iowa-based Company that specializes in patented vehicle

management technology and consultative services for reducing vehicle emissions,

improving fuel economy and lengthening the service life of heavy-duty diesel

vehicles. More information is available at ble at www.mirenco.com, or via e-mail at

info@mirenco.com or by calling

800.423.9903.

Some of the statements made in this press release are forward-looking in

nature. Actual results may differ materially from those projected in

forward-looking statements. Additional information concerning Mirenco, Inc. can

be found within Mirenco's filings with the Securities and Exchange Commission.

Statements in this release should be evaluated in light of this additional

information.

Contact Information:

Dwayne Fosseen

fosseen@mirenco.com

800-423-9903

|